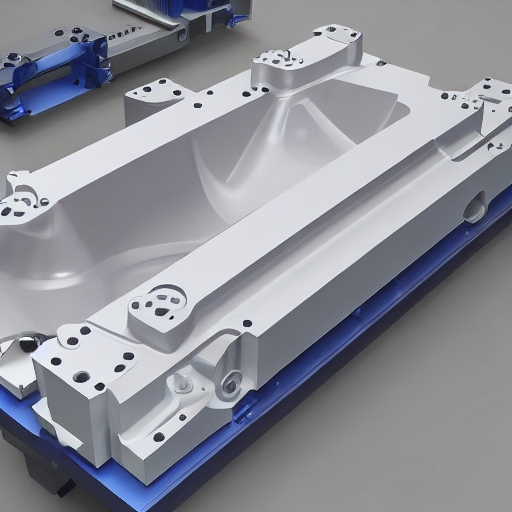

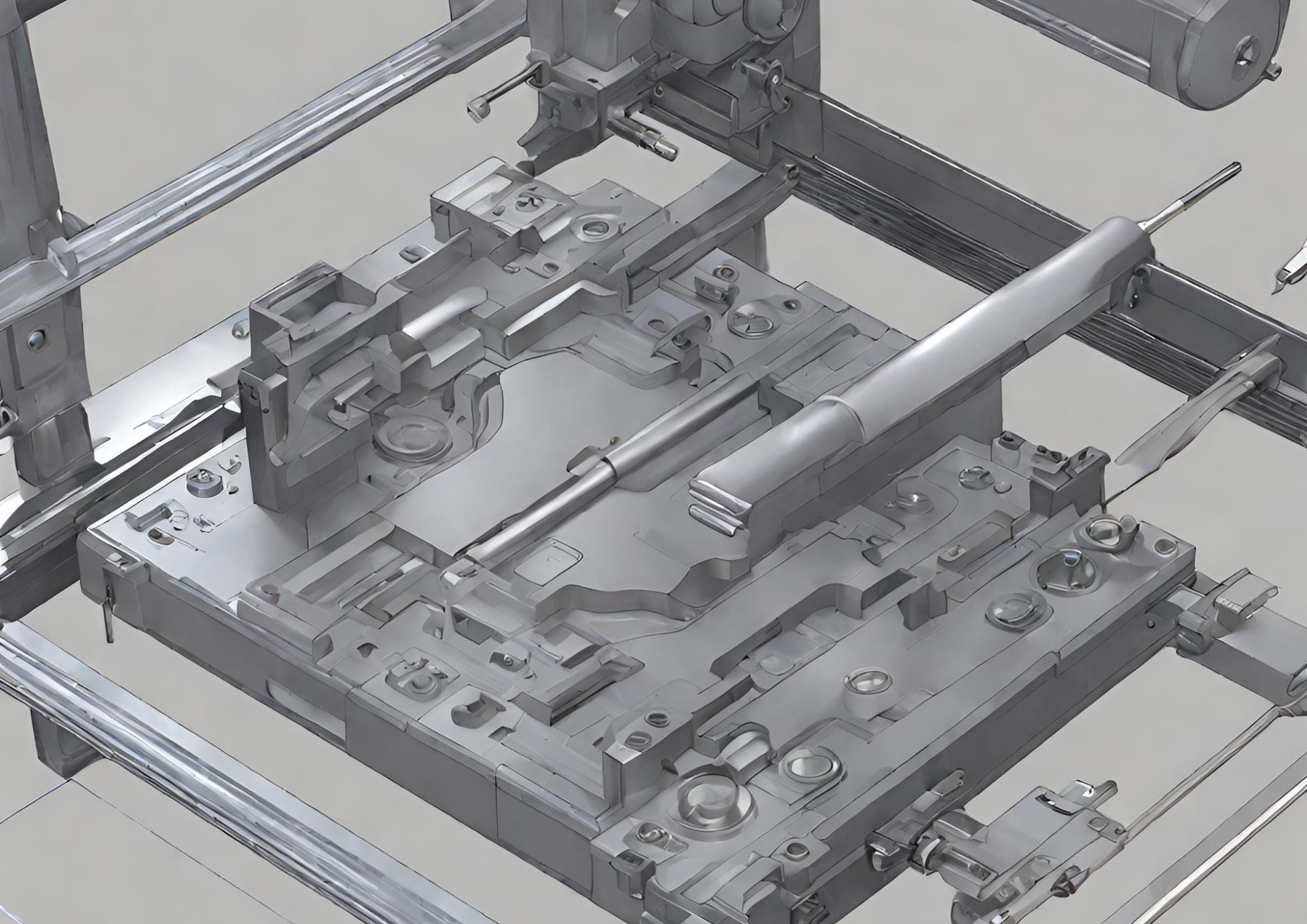

Increased competition and changes in consumer behaviour necessitate that companies develop new products at a faster pace than before. Mutual Industries, a trusted partner to our customers supports this cause completely and ensures shorter program/product development cycles with an in-house tool design and Mould Design & Development shop.

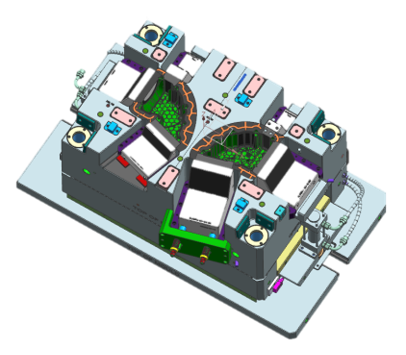

The tool shop comprises of a fully equipped Computer Numerical Control (CNC) based machine shop, EDM and assembly set up capable of manufacturing moulds for parts of sizes up to 3 m x 2 m with a weight of up to 40 Metric Tons.

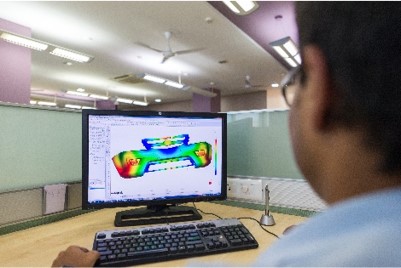

Backed by our experience and expertise of the past 35+ years in developing, tooling and processing plastic components, Mutual Industries has added a design engineering centre to support customers with end-to-end solutions from part concept stage to mass production and system supplies.

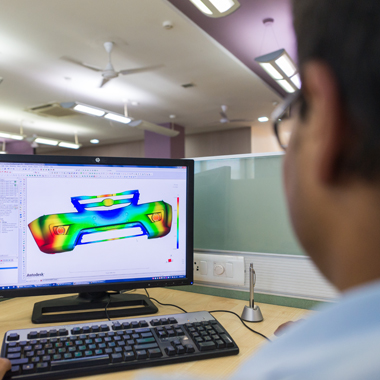

| Engineering Capabilities – CAD | Engineering Capabilities – Simulation | Engineering Capabilities – Validation |

|---|---|---|

| 3D Modeling | Static Linear | Gap & Flush on fixture |

| B Surface Modeling | Static Non Linear | Color Fading(Stiffness) |

| Assembly DMU Checking | Quasi Static | Assembly Trials, Servicing Trial |

| 2D Drawing Creation | Crash Analysis | Vibration Durability Test |

| Tolerances & Annotation | Model Analysis | Odour Test |

| Mold Design | Stiffness Analysis | Thermal Cycle Test |

| 2D Detailing | Pressure Analysis | Humidity Resistance Test |

| - | Optimization | Long Term Heat Test |

| - | FEA – TEST Correlation | Short Term Heat Test |

| - | Linear / Non Linear Durability | Fogging Test |

| - | NVH | - |

Product concept & design is a critical step in the engineering product design process. This step identifies critiques and prioritizes design concepts that meet customer needs and specifications to derive the optimal design. Decisions made during early design stages can tightly constrain future options. Developing attractive product concepts requires fluid abstract thinking, creative imagination and innovation.

We innovate new product concepts using a creative team with diverse backgrounds, expertise and perspectives.

When it comes to high-quality prototypes, there’s no one better for the job than the product development team at Mutual Industries, We are unmatched in our ability to rapidly create functional, highly-aesthetic and refined product modelling and prototyping using our in-house team and equipment, regardless of the stage of your idea.

Increased competition and changes in consumer behaviour necessitate that companies develop new products at a faster pace than before. Mutual Industries, a trusted partner to our customers supports this cause completely and ensures shorter program/product development cycles with an in-house tool design Development shop.

The tool shop comprises of a fully equipped Computer Numerical Control (CNC) based machine shop, EDM and assembly set up capable of manufacturing moulds for parts of sizes up to 3 m x 2 m with a weight of up to 40 Metric Tons

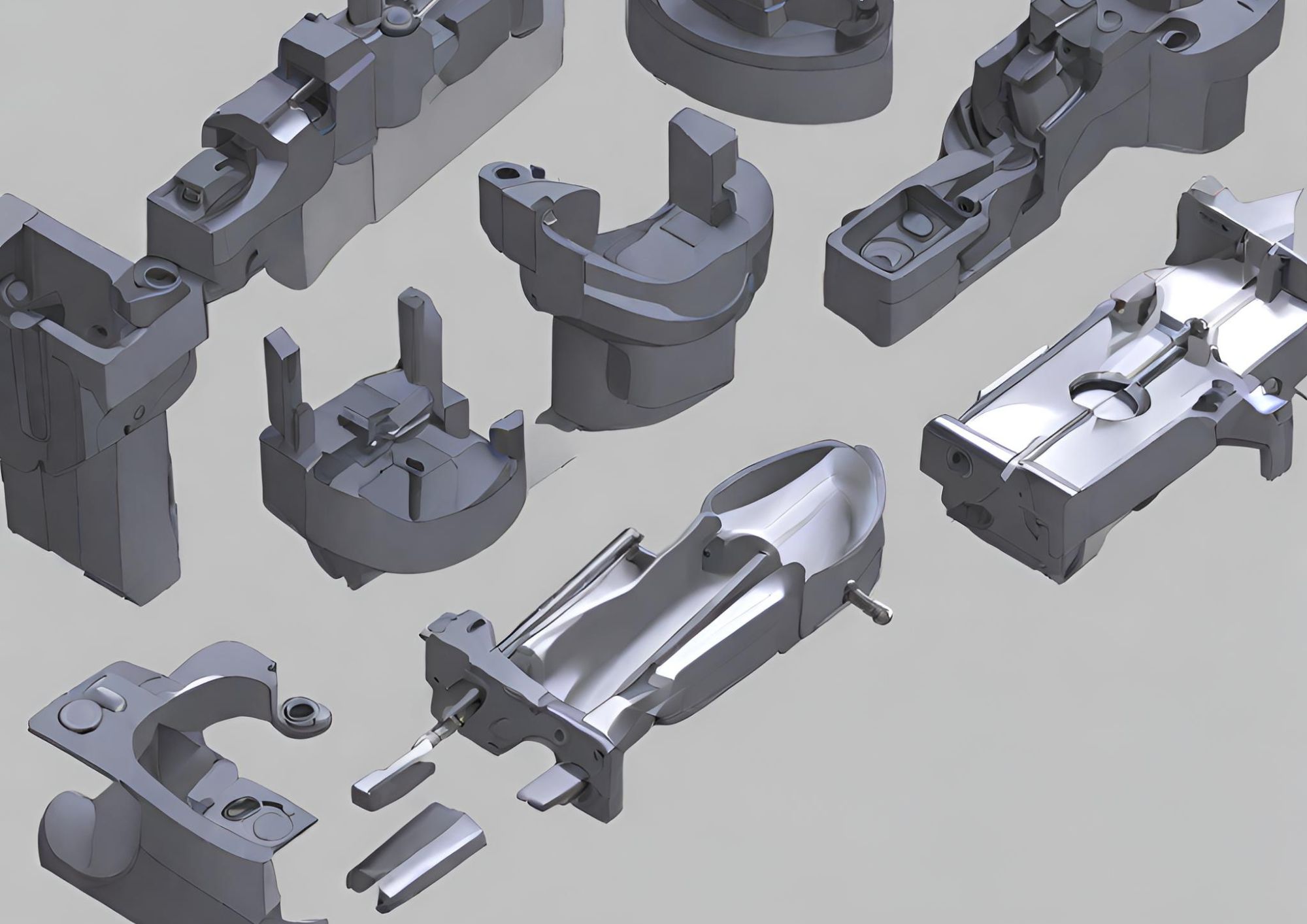

Mutual processes plastics across a wide range of polymer families right from polyolefins to Engineering polyamides, styrenes and various special compounds to meet the precise needs of the parts using injection moulding technology.

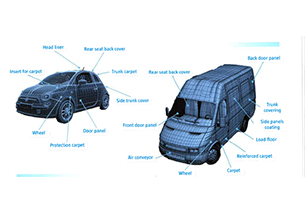

We mould parts from sizes as small as a button to as large as the front hood of a heavy commercial vehicle addressing both the technical and aesthetic requirements of the products.

We pride ourselves in employing the most contemporary technology in our machines ranging up to 3200 tons across reputed brands in the industry.

We also have the expertise of manufacturing with long fibre injection molding, gas assisted injection molding, hybrid thermoplastic composite molding, injection compression molding.

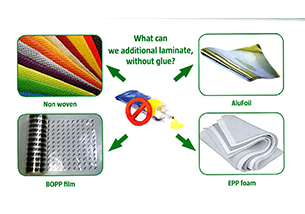

Mutual brings in the advantage of heavy gauge thermoforming using single & twin sheet technology to open up whole new possibilities of products and applications across the industry segments.

The experience of over 5 decades of Styl’monde (France) in European Industry synergizes with the indigenous engineering and manufacturing capabilities of Mutual to form Mutual Stylmonde Pvt Ltd.

It is capable to produce components up to 3mts x 2mts with most contemporary technology installments.

The applications include

Here are some potential advantages of single & twin sheet engineering thermoforming

Typical materials which can be used in single & twin sheet engineering thermoforming include: HDPE, PMMA-ABS, ABS, TPO, PC, PC-ABS, ASA, ASA-ABS, TPU–ABS, PS, PSPE, HIPS.

Mutual Industries Limited, launched its latest Technology – Mutual Bubble Guard – a range of multi-layered PP boards with a unique circular structure made with a latest European technology. The boards range from tough and rigid to soft and flexible and designed to provide customized solutions.

Mutual offers bubble guard for Automotive applications, Protection, Packaging, Printing and Panelling that find usage across industries like construction, Automotive, Electricals, Healthcare , Infra+Realty , Mass Transit, furniture, Food &Beverages, advertising, decor and logistics, and much more. The Bubble Guard technology is widely accepted worldwide especially in Europe and USA. The advantage lies in its specially engineered structure, the product is highly customizable and thus commercially viable as it saves time and effort.

Mutual Bubble Guard is a sustainable solution as It is re-usable multiple times and also recyclable, helping to reduce carbon footprint as compared to conventional materials bringing in a green solution.

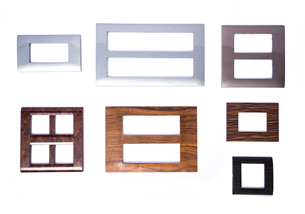

Mutual Industries brings Japanese technology from Taica Corporation ( Cubic) that enables transformation of your products through surface enhancement to augment its beauty. The process called Aqua graphics entails a water-soluble film, covered in natural and abstract prints that is printed onto substrates which could be made out of plastic, glass, wood, metal etc.

It is possible to create more than 2000 different patterns across various colour shades on the products.

Aqua graphics finds excellent applications in automotive interiors, personal care packaging, architectural products, home appliances etc

Besides the above, the decoration also adds great aesthetic value to products in the switch and lighting industry.

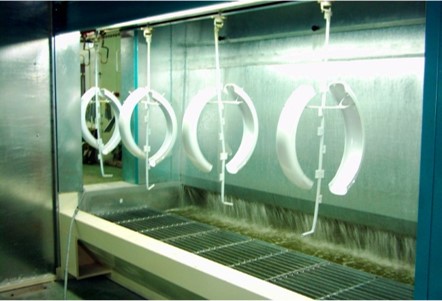

keeping with our commitment of state-of-the-art infrastructure and to provide our customers nothing but the best, Mutual Industries has invested heavily in the latest finishing technologies and are a house of excellence for plastic parts surface finish.

In India we were the first to foresee the need within the automotive hangout parts for fully automated surface finishing processes equipped with robotic paint application systems and the first five stage power wash.

Our facilities have the ability to process all solvent borne and water-borne paint technologies with the expertise to produce primer less products that surpass customer expectations. Mutual Industries has full control of the paint-able surface as we have the in-house capability to begin with mould design and manufacturing to mass production.

“feel what you see” Three-dimension Overlay Method "TOM" issued for many kinds of industrial product as the entirely new decoration method in which high design film can be decorated on the surface of your product. Tom makes it possible to express rich texture on your product. “Tom film” can design a real wooden texture, leather texture , carbon texture and many more that we can think of.

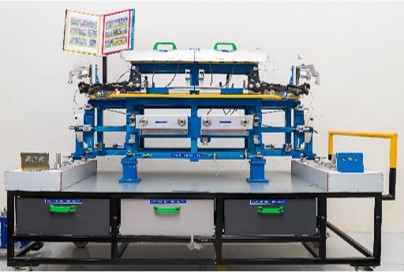

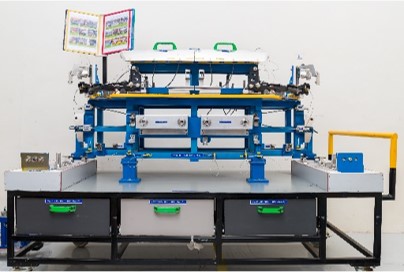

Mutual Industries produces a wide variety of accessory assembly for various applications across a various industries. The equipment we run for assembly solutions is unmatched in the industry with type of machines which are capable of placing any part in existence. We are dedicated to offering any assembly solutions at the highest levels of flexibility, complexity and reliability.